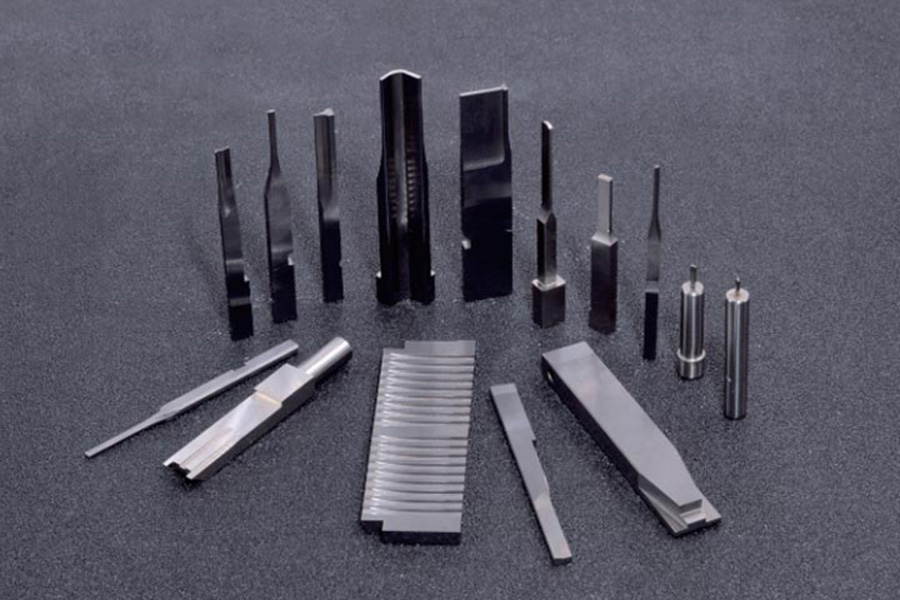

Carbide punches with key grooves are specialized tooling components typically used in precision stamping, forming, or punching operations. They are widely used in stamping tools and press dies in many industries.

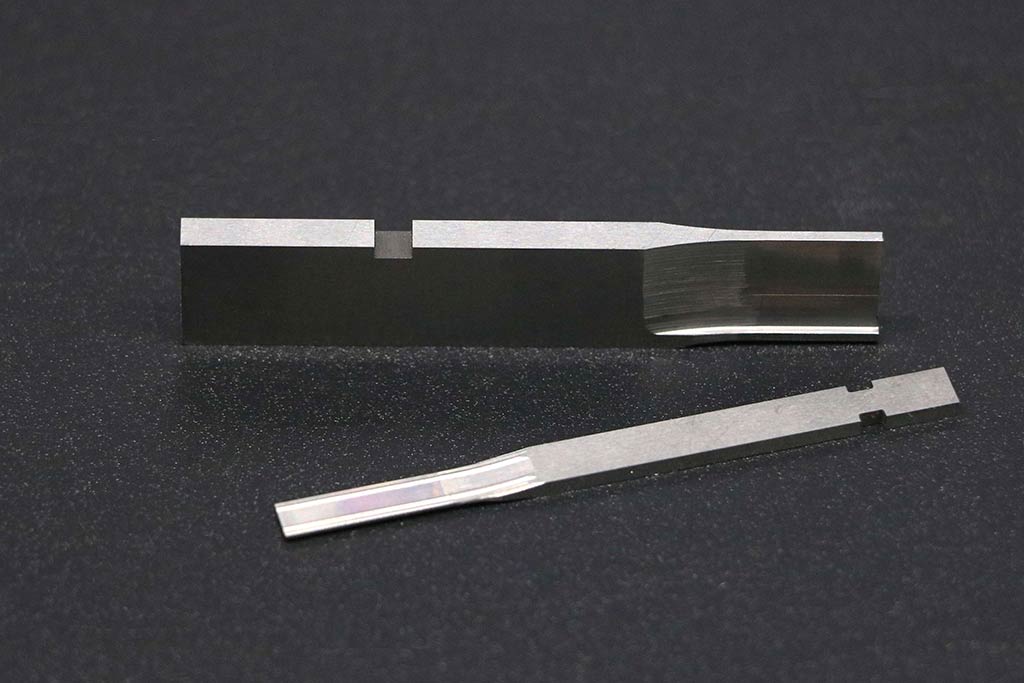

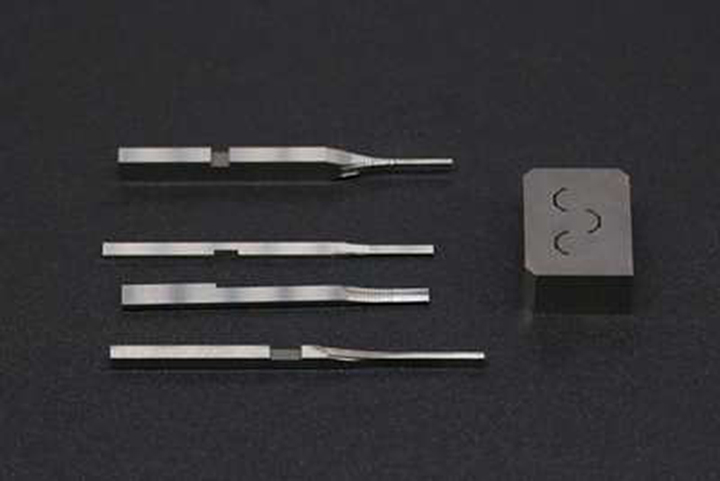

Carbide punch with key groove is a kind of punch design with key groove machined feature. It has a flat or recessed area along the body of the punch. This key groove is designed for Anti-rotation, Precise indexing, and Secure fit.

There are standard parts for these special carbide punches; There are also custom-made parts. If you need a custom-made one, we may purchase the standard parts and continue the machining to get the custom required shape. We can also make the custom carbide punches with key grooves entirely in a precision machining factory.

Application of Custom Carbide punches with key grooves

As we mentioned above, these custom carbide punches are widely used in many stamping tools and industries. These tools and industries include:

- Stamping Dies – Blanking, piercing, and forming.

- Progressive Dies – High-speed punching operations.

- Fine Blanking – Precision components for automotive/aerospace.

- Electronics & Medical – Micro-punching for small, intricate parts for Motor core lamination stamping and Microelectronics and semiconductor tooling.

The material of carbide punches has different grades according to customers’ requirements. E.g., ultra-fine grain for toughness or submicron grain for wear resistance.

Some of them need coatings (like TiN, TiCN, DLC) to further enhance life and reduce friction.

Manufacturing Process of Custom Carbide Punches

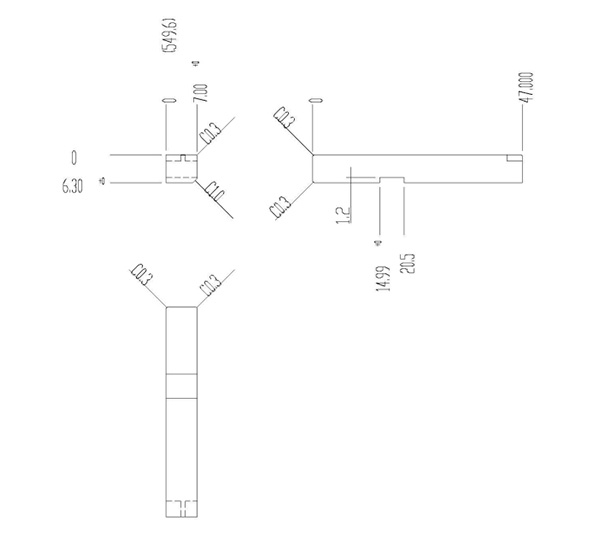

CNC Grinding – Precision surface grinding and profile grinding are mostly required to ensure tight tolerances and smooth finishes.

Wire EDM – Used for intricate shapes and sharp edges, and for creating precise key grooves.

Quality Inspection – Dimensional checks with CMM, projector, tool microscope, hardness testing, and surface finish analysis.

There are many benefits of carbide punches.

- Extended Tool Life – Reduces downtime and replacement costs.

- High Precision – Maintains consistent part quality in high-volume production.

- Reduced Wear – smooth grinding finish is ideal for abrasive materials.

- Secure Fit – Key grooves prevent misalignment during operation.

So that’s all about the topic of custom carbide punches with key grooves. If you are interested in this, please contact us at: sales@langdi-precision.com +86-15338374626 (WhatsApp).

Can you make custom carbide punches?

https://shorturl.fm/NXwds

https://shorturl.fm/aFjcV

https://shorturl.fm/ac3BE

https://shorturl.fm/aQER1

https://shorturl.fm/Vnww7

https://shorturl.fm/jKII3

https://shorturl.fm/8VmXN

https://shorturl.fm/wmxxT

https://shorturl.fm/3zaL9

https://shorturl.fm/e7sha

https://shorturl.fm/QYmiZ

https://shorturl.fm/Chis9

https://shorturl.fm/K0j45

https://shorturl.fm/z5ujB

https://shorturl.fm/YmZmW

https://shorturl.fm/KxRiN

https://shorturl.fm/EkuJG

https://shorturl.fm/bHpkv

https://shorturl.fm/37ZYU

https://shorturl.fm/i74sK

https://shorturl.fm/JSKtl

https://shorturl.fm/fgS8g

https://shorturl.fm/W6iKu

https://shorturl.fm/2i8kt

https://shorturl.fm/3MH2Q

https://shorturl.fm/psL6P

https://shorturl.fm/fz5yQ

https://shorturl.fm/sbHIB

https://shorturl.fm/C6rbf

https://shorturl.fm/4g9MQ

https://shorturl.fm/OSGBw

https://shorturl.fm/VVCUR

https://shorturl.fm/RIDf6

https://shorturl.fm/AlRX5

https://shorturl.fm/SRTuK

https://shorturl.fm/7N9h1

https://shorturl.fm/qU1KF

https://shorturl.fm/btwep

https://shorturl.fm/YEnwf

https://shorturl.fm/zzVm0

https://shorturl.fm/xZ3Qz

https://shorturl.fm/3vUnC

https://shorturl.fm/u7QEL

https://shorturl.fm/DxBJx

https://shorturl.fm/Q419r

https://shorturl.fm/ZMWGE

https://shorturl.fm/txY7C

https://shorturl.fm/7mDha

https://shorturl.fm/1eNuh

https://shorturl.fm/jQICy

https://shorturl.fm/WJsZ8

https://shorturl.fm/HcenR

https://shorturl.fm/cb0sJ

https://shorturl.fm/XcwwD

https://shorturl.fm/s5Ais

https://shorturl.fm/LoP8l

https://shorturl.fm/P09xf

https://shorturl.fm/6oMTE

https://shorturl.fm/BhXUP

https://shorturl.fm/3HgBL

https://shorturl.fm/fuXPW

https://shorturl.fm/L4mnG

https://shorturl.fm/FMs1u

https://shorturl.fm/Edb46

https://shorturl.fm/iA3KB

https://shorturl.fm/4oyR3

https://shorturl.fm/Vbiru

https://shorturl.fm/vHzCy

https://shorturl.fm/HGl5k

https://shorturl.fm/DUU19

https://shorturl.fm/w0qJ0

https://shorturl.fm/UXEmg

https://shorturl.fm/vjOQg

https://shorturl.fm/SRB7e

https://shorturl.fm/pnAvW

https://shorturl.fm/ApOmp

https://shorturl.fm/oE8oh

https://shorturl.fm/R0qvX

https://shorturl.fm/yZQAg

https://shorturl.fm/f0EDd

https://shorturl.fm/R0qvX

https://shorturl.fm/fknOI

https://shorturl.fm/j2NA3

https://shorturl.fm/hWoXB

https://shorturl.fm/0i4pR

https://shorturl.fm/6UCKo

https://shorturl.fm/lvD5R

https://shorturl.fm/9czf3

https://shorturl.fm/aSPsm

https://shorturl.fm/XNfZv

https://shorturl.fm/Gtk3I

https://shorturl.fm/ReNQJ

https://shorturl.fm/Meznh

https://shorturl.fm/Meznh

https://shorturl.fm/64zRU

https://shorturl.fm/Tjeud

https://shorturl.fm/0z7rB

27zx70

https://shorturl.fm/xdsGk

https://shorturl.fm/Wh1od

https://shorturl.fm/vNzbx

https://shorturl.fm/nnJjH

https://shorturl.fm/ekuRK

https://shorturl.fm/PFXZN

https://shorturl.fm/mMfyI

https://shorturl.fm/SpMkE

https://shorturl.fm/BiPjb

https://shorturl.fm/dzr4R

https://shorturl.fm/prDMA

https://shorturl.fm/1Y0ym

https://shorturl.fm/kdzUw

https://shorturl.fm/Mw4t6

https://shorturl.fm/0MfQ6

https://shorturl.fm/d5IzO

https://shorturl.fm/1xXYQ

https://shorturl.fm/kISmX

https://shorturl.fm/uo8fE

https://shorturl.fm/6AwNQ

https://shorturl.fm/LZnmM

7e530m

https://shorturl.fm/OZDTd

https://shorturl.fm/lcK9y

https://shorturl.fm/5FZWn

https://shorturl.fm/tt7e2

https://shorturl.fm/lqUUf

https://shorturl.fm/B1Fzv

https://shorturl.fm/qkxJG

https://shorturl.fm/fhK72

https://shorturl.fm/X7E49

https://shorturl.fm/TpDJj

https://shorturl.fm/cT4Ro

https://shorturl.fm/Qv5pS

https://shorturl.fm/7eTzy

https://shorturl.fm/E4Heq

https://shorturl.fm/1G9qu

https://shorturl.fm/VVtog

https://shorturl.fm/IcgiA

https://shorturl.fm/Qg4UV

https://shorturl.fm/0hn6B

https://shorturl.fm/vKfN9

https://shorturl.fm/Zhph1

https://shorturl.fm/C3oGO

https://shorturl.fm/kdwdh

https://shorturl.fm/UrAYn

https://shorturl.fm/3mnZr

https://shorturl.fm/4FXwP

https://shorturl.fm/XVM01

https://shorturl.fm/HodDB

https://shorturl.fm/RhGLg

https://shorturl.fm/ZdB7L

https://shorturl.fm/HLin0

https://shorturl.fm/aEfQb

https://shorturl.fm/PA8iX

https://shorturl.fm/fmxbz

https://shorturl.fm/fqCfa

https://shorturl.fm/YYIRJ

https://shorturl.fm/UR5h9

https://shorturl.fm/Rrwxn

https://shorturl.fm/6CncJ

https://shorturl.fm/Ib59o

https://shorturl.fm/o93YL

https://shorturl.fm/XymGo

https://shorturl.fm/uB4bH

https://shorturl.fm/hqeRt

https://shorturl.fm/q4B4A

https://shorturl.fm/d3exY

https://shorturl.fm/5Xw2X

https://shorturl.fm/nxFN3

https://shorturl.fm/wGwY2

ws6kwv

https://shorturl.fm/oyKxh

https://shorturl.fm/vFwdv

https://shorturl.fm/1S9oM

https://shorturl.fm/EyIr1

https://shorturl.fm/DZfAv

https://shorturl.fm/cJLLq

https://shorturl.fm/pGgco

https://shorturl.fm/DKusN

https://shorturl.fm/94aZF

https://shorturl.fm/rNY3V

https://shorturl.fm/OlIrV

https://shorturl.fm/2KkHe

https://shorturl.fm/XPBMp

https://shorturl.fm/k6pZe

https://shorturl.fm/QHb03

https://shorturl.fm/plB7K

https://shorturl.fm/If7bM

https://shorturl.fm/RRTEg

https://shorturl.fm/g1cKy

https://shorturl.fm/QokL5

https://shorturl.fm/Vu6T4

https://shorturl.fm/byhpv

https://shorturl.fm/FcVPB

https://shorturl.fm/TRzyO

https://shorturl.fm/D5iIr

https://shorturl.fm/u3uXB

https://shorturl.fm/ypc4L

https://shorturl.fm/baG6J

https://shorturl.fm/x3UpT

https://shorturl.fm/WeRBr

https://shorturl.fm/Svpqc

https://shorturl.fm/614lX

https://shorturl.fm/ert6h

https://shorturl.fm/2CelU

https://shorturl.fm/MHOQk

https://shorturl.fm/UPNzl

https://shorturl.fm/y17nH

https://shorturl.fm/XIDa8

https://shorturl.fm/2iD1B

https://shorturl.fm/uiTI1

https://shorturl.fm/OQeil

https://shorturl.fm/NNuJU

https://shorturl.fm/VWyzE

https://shorturl.fm/lK1TI

https://shorturl.fm/WSrvQ

https://shorturl.fm/boooV

https://shorturl.fm/f21U7

https://shorturl.fm/iJzhF

https://shorturl.fm/KQGE7

https://shorturl.fm/V2FVE

https://shorturl.fm/crlVe

https://shorturl.fm/Xfw61

https://shorturl.fm/Zx5Nc

https://shorturl.fm/dHd93

https://shorturl.fm/yceFM

Lodibetlogin is my go-to when I’m trying to place a quick bet. The login process is smooth as butter, none of that annoying lag I’ve seen on other sites. Super easy to get in and get betting! Give it a shot: lodibetlogin

https://shorturl.fm/Vaah6

https://shorturl.fm/CllJe

https://shorturl.fm/JT5eS

https://shorturl.fm/X1zIs

https://shorturl.fm/R06FM

https://shorturl.fm/bJGxY

https://shorturl.fm/2E8il

https://shorturl.fm/Tu8he

https://shorturl.fm/F75pK

https://shorturl.fm/OjkXH

https://shorturl.fm/OQqne

https://shorturl.fm/EPbD7

https://shorturl.fm/wu3l4

https://shorturl.fm/onuqP

https://shorturl.fm/RIKfB

https://shorturl.fm/2RKc4

https://shorturl.fm/AsU4d

https://shorturl.fm/xn7VE

https://shorturl.fm/F8Nmy

https://shorturl.fm/meCQc

https://shorturl.fm/1X4Q8

https://shorturl.fm/SZdQ9

https://shorturl.fm/BQJRB

https://shorturl.fm/4SO5v

https://shorturl.fm/Npy96

https://shorturl.fm/mgrQO

https://shorturl.fm/q3wEc

https://shorturl.fm/lYIXv

https://shorturl.fm/ar7XP

https://shorturl.fm/NHpPr

https://shorturl.fm/oYget

https://shorturl.fm/WR0FT

https://shorturl.fm/378PO

https://shorturl.fm/uleRM

https://shorturl.fm/0nYry

https://shorturl.fm/9uqDl

https://shorturl.fm/KUqsw

https://shorturl.fm/2kD1b

https://shorturl.fm/udN76

https://shorturl.fm/eWbu8

https://shorturl.fm/haD3K

https://shorturl.fm/omUZv

https://shorturl.fm/gxCMP

https://shorturl.fm/vhUg0

https://shorturl.fm/Nw69N

https://shorturl.fm/lhWOe

https://shorturl.fm/JpE8i

https://shorturl.fm/48bdf

https://shorturl.fm/6LSBB

https://shorturl.fm/a4Cqf

https://shorturl.fm/hoA9G

https://shorturl.fm/cts5u

https://shorturl.fm/0N527

https://shorturl.fm/hpxhb

https://shorturl.fm/oc0en

https://shorturl.fm/picRe

https://shorturl.fm/jH8ok

https://shorturl.fm/ZCuoq

https://shorturl.fm/JM5rq

https://shorturl.fm/ID3qM

Enter your invite code to earn your airdrop on Aster https://is.gd/ZceEI6

Earn your airdrop on Aster https://is.gd/ZceEI6

It’s really a great and helpful piece of info. I am glad that you shared this helpful info with us. Please keep us informed like this. Thank you for sharing.

Hi https://is.gd/9PLRLO

Hello https://is.gd/tvHMGJ

Get started instantly—earn on every referral you make!

Join our affiliate program today and start earning up to 30% commission—sign up now!

Refer friends, collect commissions—sign up now!

Become our affiliate and watch your wallet grow—apply now!

Be rewarded for every click—join our affiliate program today!

Refer friends and colleagues—get paid for every signup!

Share your link, earn rewards—sign up for our affiliate program!

Drive sales and watch your affiliate earnings soar!

Unlock exclusive rewards with every referral—enroll now!

Your influence, your income—join our affiliate network today!

Join our affiliate community and maximize your profits!

Partner with us for high-paying affiliate deals—join now!

Boost your earnings effortlessly—become our affiliate!

Monetize your audience with our high-converting offers—apply today!

Become our partner and turn referrals into revenue—join now!

Boost your profits with our affiliate program—apply today!

I really value your piece of work, Great post.

Get rewarded for every recommendation—join our affiliate network!

Join our affiliate program and start earning commissions today—sign up now!

Turn your audience into earnings—become an affiliate partner today!

Apply now and receive dedicated support for affiliates!

ywd8kp

9dye93

Earn big by sharing our offers—become an affiliate today!

Drive sales and watch your affiliate earnings soar!

Maximize your income with our high-converting offers—join as an affiliate!

Share your unique link and earn up to 40% commission!

Monetize your audience with our high-converting offers—apply today!