Carbide punches are one of the key components used in various manufacturing processes, particularly in industries like sheet metal stamping and cutting. Tungsten carbide punch is used with a die insert together as a full punch and die set.

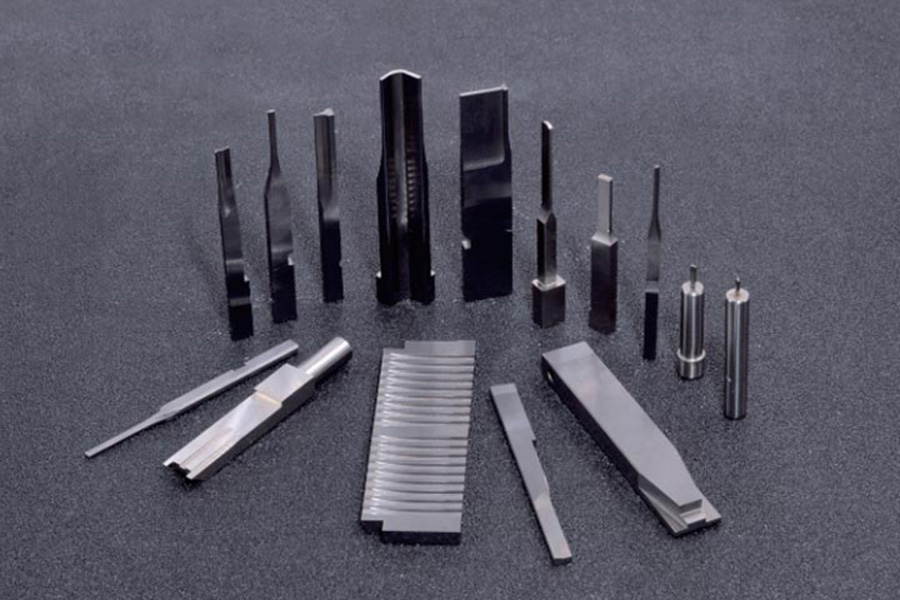

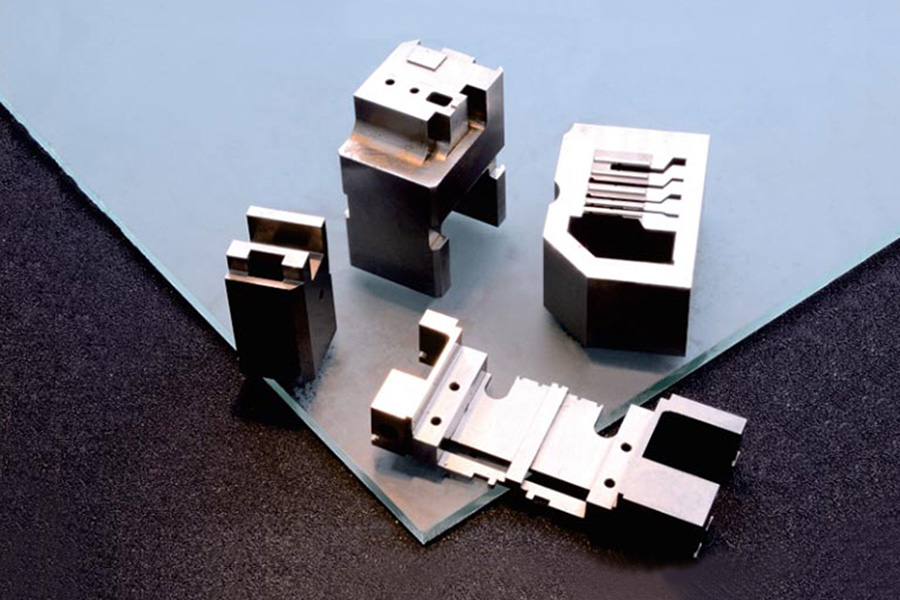

Custom Carbide Punches Pictures

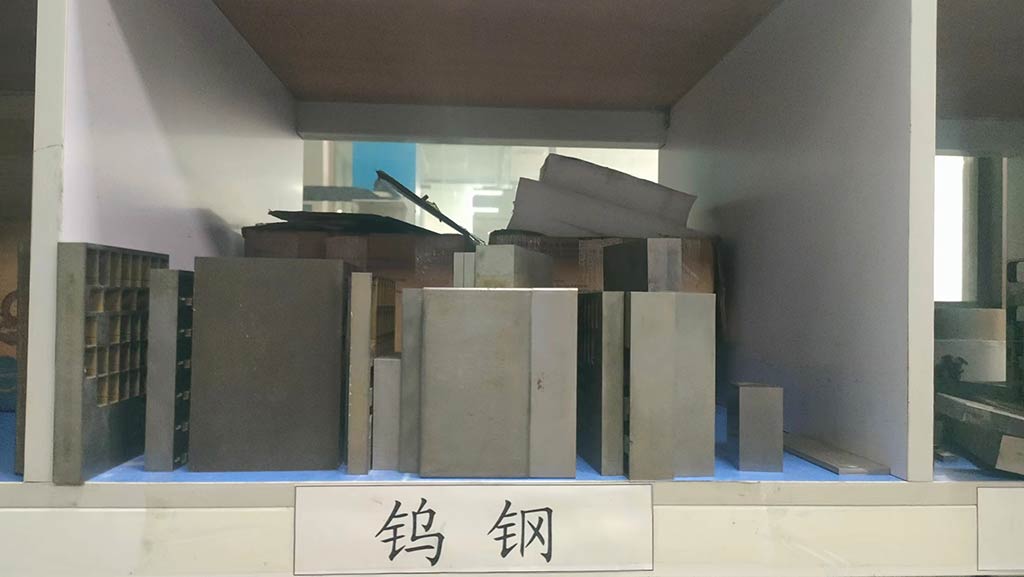

They are made from carbide, and some are made from PM or HSS. But carbide is the best choice, as it is a hard metal material known for its hardness, wear resistance, and durability. There are various kinds of carbide brands and models, like Fujilloy, Sanalloy, Everloy, Cbceratizit, etc. Some commonly used carbide models are KD20, RD50, KX03, RG3, FD15, FD25, GA20, H40S and CD650, etc.

Let’s see some of the key features and applications of carbide punches:

Carbide Punches Features

Hardness:

Carbide punches are extremely hard and can withstand high-pressure applications without deforming or breaking. This hardness makes them ideal for use in punching operations where a sharp and durable tool is required.

Wear Resistance:

Carbide punches have excellent wear resistance, meaning they maintain their sharpness and dimensional accuracy even after prolonged use. This property extends the tool’s lifespan and reduces the need for frequent replacements.

Precision:

Carbide punches can be manufactured with high precision, ensuring consistent and accurate results in punching and forming operations. This precision is crucial in industries where tight tolerances are required.

Cost-effectiveness:

While carbide punches may have a higher upfront cost compared to traditional tooling materials, their durability and performance often result in long-term cost savings. Reduced downtime and tool replacement costs contribute to their overall cost-effectiveness.

Carbide Punches Applications

Carbide punches can be used with a variety of materials, including metals, plastics, ceramics, and composites. They are used for tasks such as punching, stamping, forming, and shaping materials.

They are suitable for punching sheet metal, punching holes, forming shapes, embossing, and other similar tasks across different materials.

They are essential tool components in many manufacturing processes. Especially in the microelectronics manufacturing process. For example, micro connectors and micro terminal blocks, cellphone and computer components, etc.

Carbide Punch Types

There are various types of carbide punches. According to shape classification, some are cylindrical carbide punches, some are rectangular and square-shaped punches.

There are some standard punch brands like Dayton carbide punches, Misumi carbide punches, lifetime carbide punch and die set. But most of the punches are custom-made according to specific designs and drawings.

These custom punch types may be called as below:

Carbide blank punches

Carbide forming punches

Carbide stamping punches

Carbide straight punches

Carbide coining punches

Carbide piercing punches

Carbide pilot punches

Profile grinding carbide punches

Carbide Punches Shortcomings

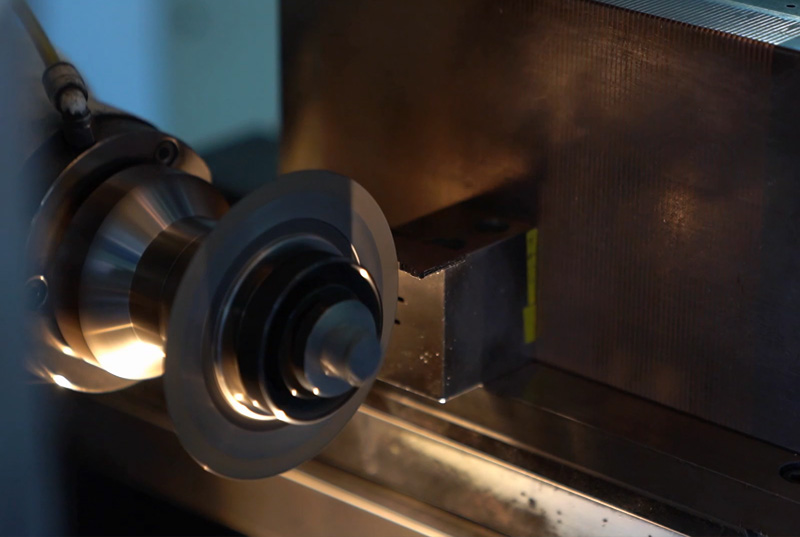

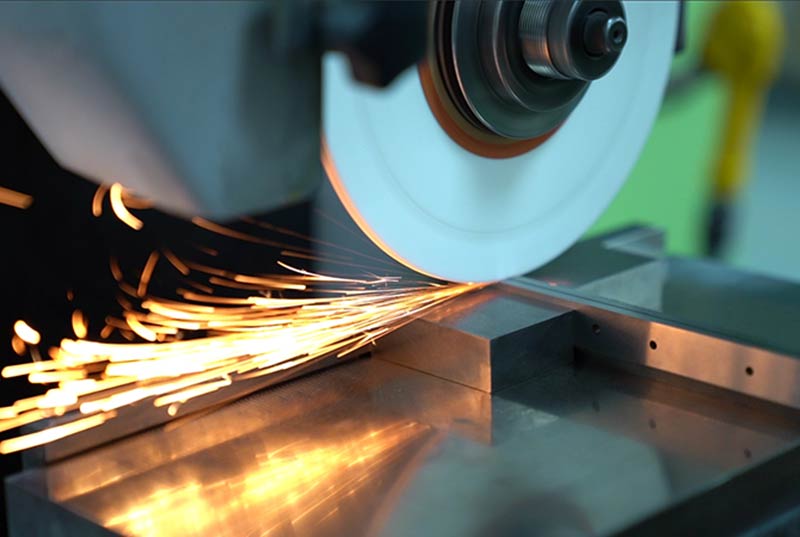

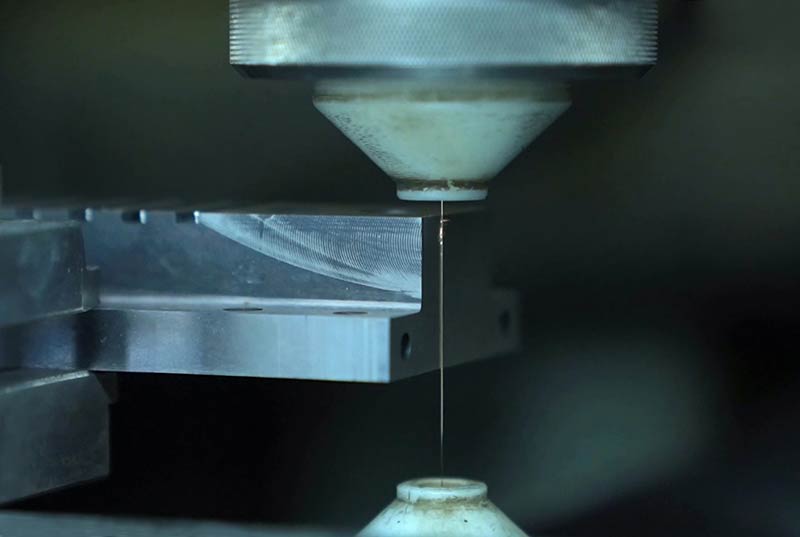

Although carbide punch has some good features, it also has some weaknesses. As it is too hard the Hardness can be around 89-95 HRC. It is not easy to process, only need to use very expensive machining equipment to process the material, for example, profile grinding and surface grinding with good-quality diamond wheels, or wire-cut EDM or Sinker EDM. So its material cost and manufacturing cost both are high.

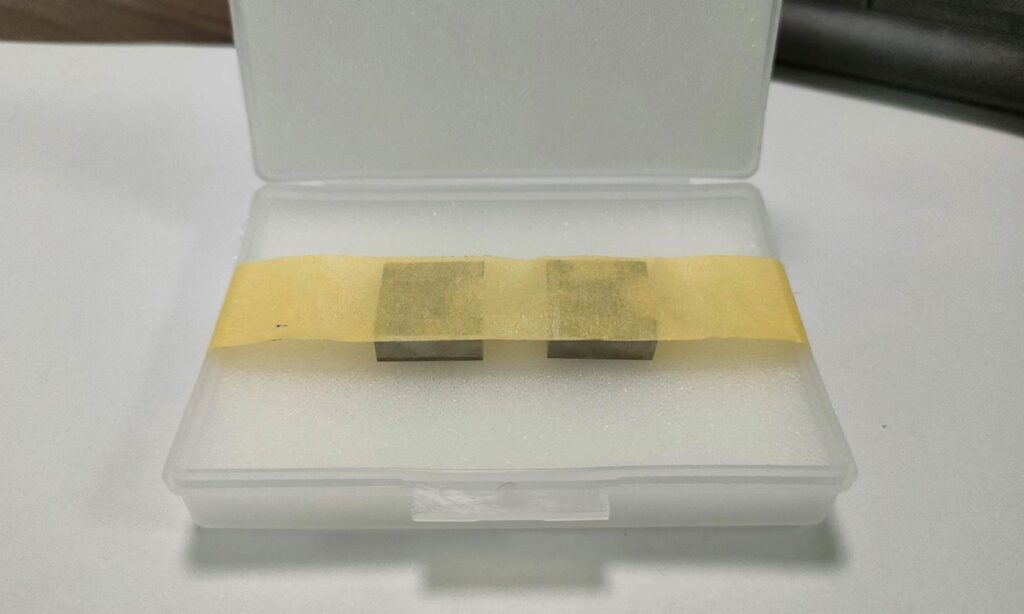

There is another weakness is that it can easily be damaged when Falling to the ground. Although it is hard, it is also crisp and easy to break. So the package is very important. Usually, it is packed in a plastic box with pearl cotton, and also fixed by a paper tape.

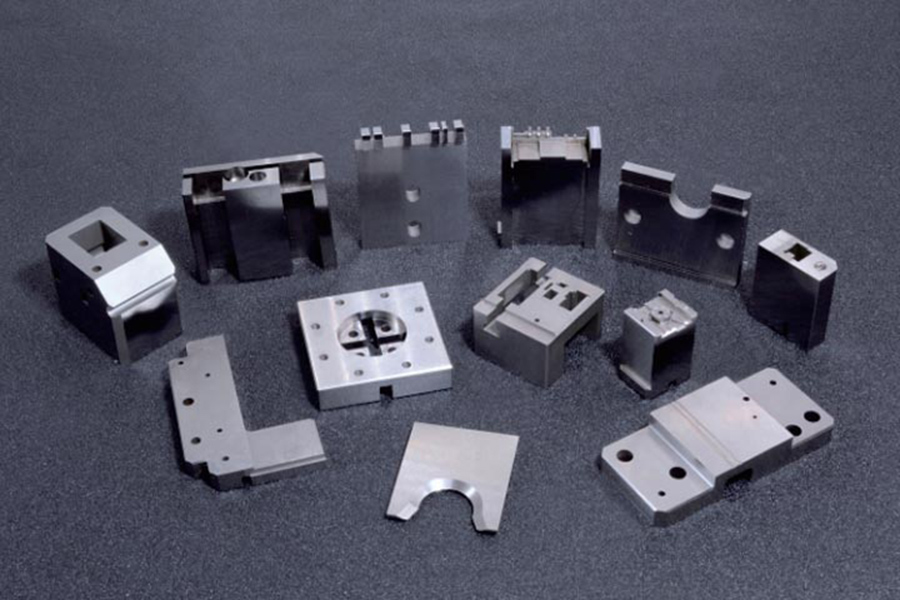

Carbide Punches and Dies

As we mentioned above, carbide punches and dies are a set of tools used together. The dies here mean the carbide die inserts with holes just matching with the carbide punches. Usually, a die insert needs to retain a clearance, slope angle, and conical angle in some places to ensure proper use.

Carbide Punch Manufacturers

There are many tungsten carbide punch manufacturers in the USA, Japan, China, and even India. Some famous brands like Oberg Industries, Endurance Carbide, Raven Carbide Die and Langdi Precision. For some carbide punch suppliers in the USA, production costs may be very high, and some carbide punch factories in China may be more Cost-effective, like Langdi Precision. It’s all by customers’ choices.

Overall, carbide punches offer superior performance and longevity compared to traditional punches made from materials like steel. The making of carbide punches is very sophisticated work that needs tough machinists and advanced machining technologies together.

If you have any needs for custom carbide punches, welcome to contact us at +86-15338374626 or email sales@langdi-precision.com.